Disinfectant Spraying Robot

Abhimanyu Khadka, Asim Maharjan, Saju KhakurelFunded by Nepal Academy of Science and Technology (NAST) during Covid-19

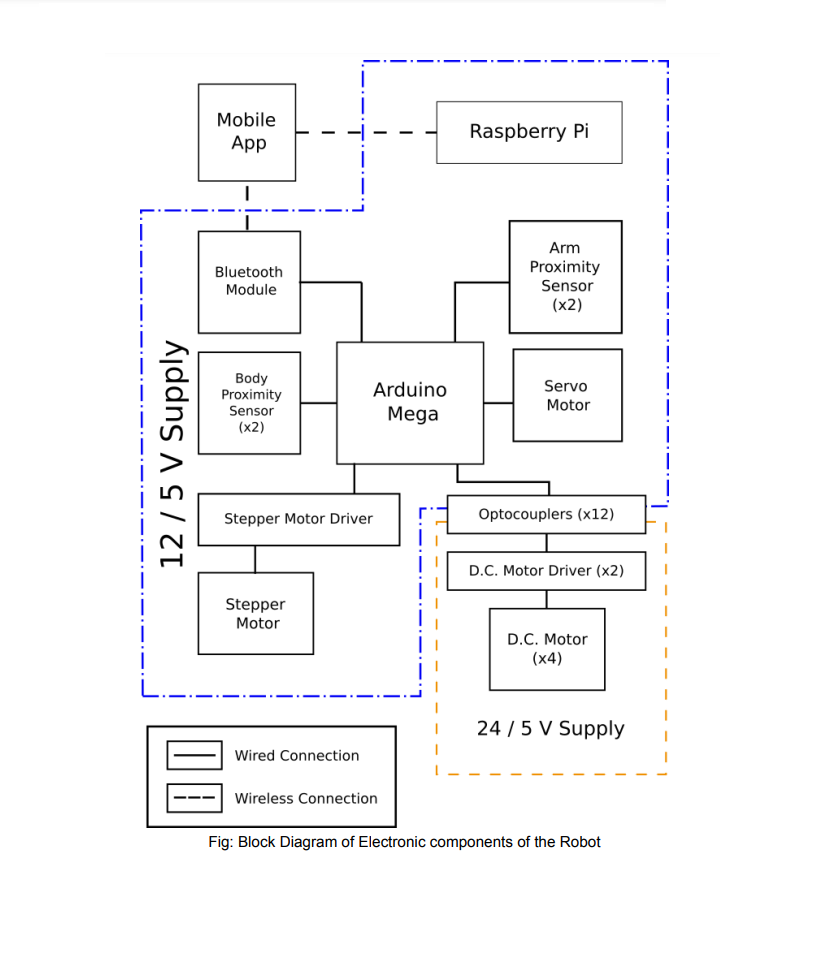

The robot uses a simple differential drive for movement and is equipped with four 24V DC motors,

with each motor controlling the rotation of a single wheel. The robot uses the Arduino Mega 2560

microcontroller for controlling the motor drivers and Bluetooth signals.

The DC Motors are controlled using an H-bridge motor driver L298N which enables the motors to be

operated both clockwise and counterclockwise. The motor driver is given a PWM input from Arduino

according to which the speed and direction of the motors are controlled.

The 2-axis arm for spraying the disinfectant is made from wood and is controlled by a stepper motor,

NEMA 17 for horizontal rotation and a servo motor MG995, for vertical movement. The stepper

motor is controlled by a stepper driver A4988 which allows for precise movement of the arm. We also

attached two proximity sensors to control the movement of the stepper motor.

A 12 V DC water pump is used for spraying the disinfectant. The water pump is made controllable by

using

a simple on/off relay switch.

The robot is also equipped with two proximity sensors which are mounted on the front and the back of

the robot. The proximity sensors are used to detect obstacles in the path of the robot and signal

the controller if any obstacle is detected .

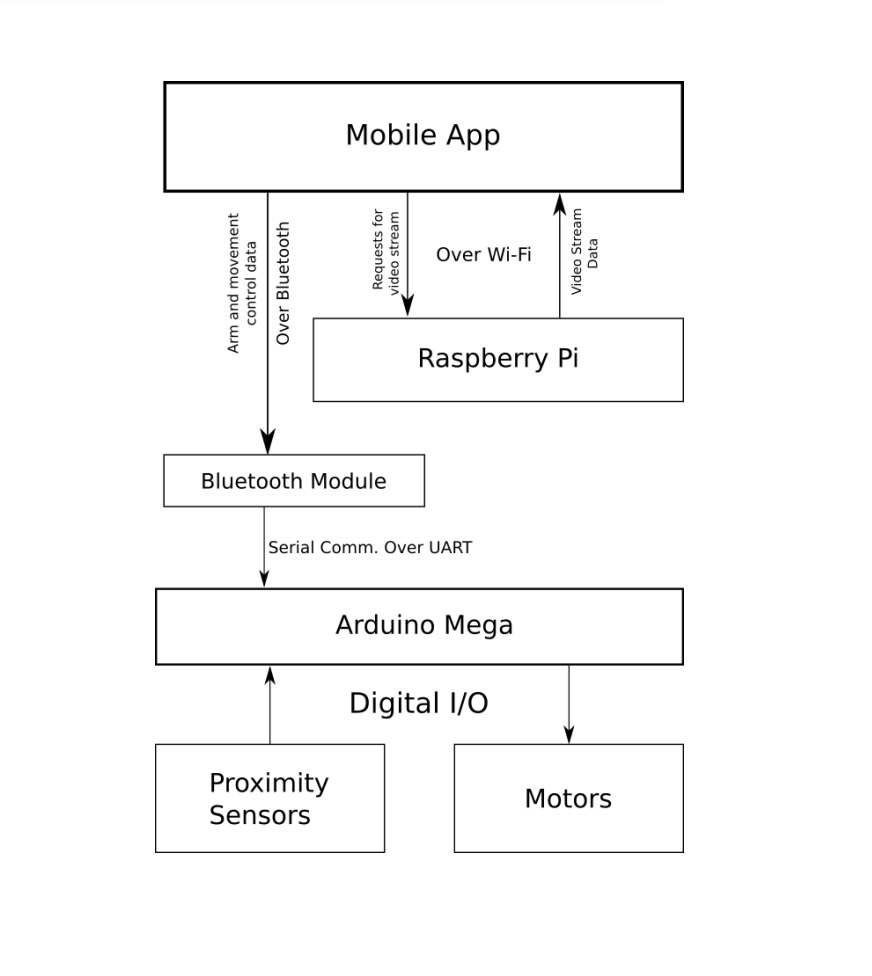

The robot also has a Raspberry Pi Model 3B+ which is used primarily for video streaming. The video

is captured through a Raspberry Pi Camera, which the raspberry pi broadcasts through WiFi to the

mobile app.

The robot is controlled by a mobile app. The mobile app uses Bluetooth to establish communication

with the robot. For this, the robot comes equipped with the HC-05 Bluetooth module. The mobile app

was created using Flutter and comes with an interface for controlling the robot as well as for

viewing the video that is captured by the robot.

The power supply for the robot is divided into two parts. One part is for powering the DC motors of

the robot while the other part powers all the other components. The motors are isolated from the

other components as the motors were found to be very noisy and it affected the operation of other

components of the robot. The isolation is done using optocouplers.